Frequently asked Questions

Nut Milk

1. What types of nut milk and ready2blend nut milk does Dat Nut Milk offer?

LOW-SUGAR MILK

- Cashew milk, beetroot cashew milk, cocoa cashew milk;

- Peanut milk, kale peanut milk, cocoa peanut milk;

- Cashew milk, beetroot cashew milk, cocoa cashew milk;

- Sugar-free cashew milk;

- Sugar-free macadamia milk;

- Sugar-free macadamia, cashew, peanut, black sesame milk.

In addition, Dat Nut Milk also provides corresponding types of butter so customers can make milk by themselves at home.

Refer to Dat Nut Milk menu here.

2. What are the ingredients in milk?

Đạt Nut Milk is made from peanut butter or cashew butter, vegetable powder (combination of flavors: beets, kale, cocoa,…), molasses, water, and salt in appropriate proportions. Details:

| Nut milk | Cashew milk | Beetroot cashew milk | Cocoa cashew milk | Peanut milk | Kale peanut milk | Choco peanut milk | Sugar-Free Cashew Milk | Sugar-free macadamia milk | Macadamia, cashew, peanut, black sesame milk | Sugar-free macadamia, cashew, peanut, black sesame milk |

|---|---|---|---|---|---|---|---|---|---|---|

| Macadamia butter | 14% | 3% | 3,53% | |||||||

| Black Sesame butter | 3,5% | 4,12% | ||||||||

| Peanut butter | 14,2% | 13,8% | 13,3% | 2,5% | 2,94% | |||||

| Cashew butter | 12,5% | 9,2% | 11,7% | 14% | 2,5% | 2,94% | ||||

| Cocoa powder | 1,1% | 1,3% | ||||||||

| Kale powder | 0,7% | |||||||||

| Beetroot powder | 0,8% | |||||||||

| Molasses | 5,0% | 5,0% | 6,1% | 5,1% | 4,4% | 7,2% | 4,92% | |||

| Salt | 0,2% | 0,1% | 0,2% | 0,04% | 0,08% | |||||

| Water | 82,5% | 85,0% | 81,0% | 80,5% | 81,0% | 78,0% | 86% | 86% | 83,54% | 86,41% |

3. Do blue, pink and brown milk products contain color additives?

No. It is the color of the vegetable powder: The pink-red color of taro, the green color of kale, and the brown color of cacao.

4. How many calories are in nut milk?

Each type of milk will have different nutritional indicators. The nutritional value per 100g of nut milk is as follows:

| Energy (kcal) | Protein (g) | Starch (g) | Fat (g) | Sugar (g) | Natri (g) | Fiber (g) | |

| Cashew milk | 84.9 | 2.5 | 6.6 | 5.5 | 4.2 | 0,0 | 0,7 |

| Beetroot cashew milk | 67.9 | 1.9 | 5.7 | 4.2 | 3.9 | 0,0 | 0.6 |

| Cocoa cashew milk | 86.9 | 2.6 | 7.3 | 5.4 | 4.8 | 0,0 | 0.7 |

| Peanut milk | 92.6 | 2.5 | 6.0 | 6.8 | 4.5 | 0,1 | 0.8 |

| Kale peanut milk | 92.6 | 2.7 | 5.8 | 6.8 | 3.9 | 0,1 | 1.0 |

| Cocoa peanut milk | 96.1 | 2.6 | 7.2 | 6.6 | 5.4 | 0,1 | 0.8 |

| Sugar-free macadamia milk | 104.2 | 1.1 | 2.0 | 10.7 | 0.0 | 0.0 | 0.0 |

| Sugar-Free Cashew Milk | 79.0 | 3.0 | 4.3 | 6.7 | 0.8 | 0.0 | 0,5 |

| Sugar-free macadamia, cashew, peanut, black sesame milk | 82.2 | 2.2 | 2.3 | 7.5 | 0.4 | 0.0 | 0.8 |

| Macadamia, cashew, peanut, black sesame milk | 66.7 | 1.8 | 1.9 | 6.1 | 0.4 | 0.0 | 0.7 |

5. What does finished nut milk look like?

6. Is the separation of milk a sign that the milk is old or spoiled?

7. Does nut milk have sugar?

8. Đạt Nut Milk provides two types of nut milk:

– LOW-SUGAR MILK: Nut milk offers the natural sweetness of molasses, not refined sugar (white or brown sugar). Due to its artisanal refinement process, Molasses has a lower sucrose content. Therefore, using molasses is better as it contains more vitamins and minerals.

9. Does nut milk contain cow’s milk?

10. Can I order hot milk?

11. Can I request adjustments to the sweetness of the milk?

12. What types of bottles are used to contain the milk?

13. Can used glass bottles be returned?

Đạt Nut Milk refunds 2,000 VND to customers for each returned glass bottle. We will collect the bottles in batches and pay in cash or directly deduct them from the value of the next order.

14. How can customers contact to buy milk? Is there an order monthly?

15. Where can customers buy nut milk?

(1) Đạt Nut Milk branches (9 am – 7 pm from Monday to Saturday):

Branch 1: 7 Cu Chinh Lan, Ward 13, Tan Binh District, Ho Chi Minh City

Branch 2: 30 Street 59, Thao Dien Ward, Thu Duc City, Ho Chi Minh City

Customers can order directly via fanpage or hotline 0336 772 305

(2) Online platforms:

Facebook: Đạt Foods

Zalo: 0336 772 305

(3) Food App

Tan Binh District: ShopeeFood | GrabFood

District 2: ShopeeFood | GrabFood

16. How much does shipping cost?

- Free shipping for orders from 50,000 VND.

- For orders less than 50,000 VND shipping fee is 10,000 VND.

- Free shipping for orders from 500,000 VND.

- Orders less than 500,000 VND Dat Nut Milk shares 50% shipping fee.

17. How long does shipping take?

- Nut milk is shipped within 2 hours of placing the order on the same day.

- Ready2Blend base is shipped within 4 hours on the same day for customers in Ho Chi Minh City.

- For customers in other provinces, delivery takes 3-5 days.

19. Can nut milk be stored for daily consumption?

20. How should nut milk be stored? What are the signs of spoiling nut milk?

21. How many glasses of milk should I drink daily to ensure energy?

22. Can diabetics drink it?

23. Can children drink milk?

24. Can people with allergies or vegetarians consume nut milk?

25. Can the elderly, children and pregnant women consume nut milk?

26. How can I get updates on promotions?

27. How can I become a retailer/distributor of Đạt Foods?

28. What are the ingredients in Ready2Blend nut milk?

| Ready2Blend nut milk | Ready2Blend cashew milk | Ready2Blend beetroot cashew milk | Ready2Blend choco cashew milk | Ready2Blend peanut milk | Ready2Blend kale peanut milk | Ready2Blend choco peanut milk | Ready2 blend sugar-free cashew milk | Ready2 blend sugar-free macadamia milk | Ready2 blend macadamia, cashew, peanut, black sesame milk | Ready2 blend sugar-free macadamia, cashew, peanut, black sesame milk |

| Macadamia butter | 100% | 18,2% | 25,9% | |||||||

| Black sesame butter | 21,3% | 30,3% | ||||||||

| Peanut butter | 73,1% | 72,7% | 60,7% | 15,2% | 21,6% | |||||

| Cashew butter | 71,3% | 61,3% | 61,8% | 100% | 15,2% | 21,6% | ||||

| Choco powder | 5,9% | 5,8% | ||||||||

| Kale powder | 3,6% | |||||||||

| Beetroot powder | 5,1% | |||||||||

| Molasses | 28,5% | 33,3% | 32,0% | 26,1% | 22,9% | 32,7% | 29,9% | |||

| Salt | 0,2% | 0,3% | 0,2% | 0,8% | 0,8% | 0,8% | 0,2% | 0,6% |

29. How to use Ready2Blend nut milk?

Dat Nut Milk suggests a milk mixing ratio as below. First, you blend Ready2Blend nut milk with water. Depending on each person’s taste, you can increase or decrease the suggested amount.

The average time for blending is no more than 2 minutes. However, depending on the device, blend until you have a smooth milk mixture. After blending, you can chill it or shake it with ice and enjoy.

If you want to use hot milk, blend Ready2Blend nut milk with hot water.NOTE: If you blend with cold water and heat the cold milk mixture on the stove or microwave, the milk will change its structure (become lumpy like a buffalo brain), unable to return to its original smooth state.

| Ordinal | Product | Ready2Blend nut milk (g) | Water (g) | Ice (g) |

| 1 | Cashew milk | 28 | 125 | 100 |

| 2 | Beet cashew milk | 28 | 125 | 100 |

| 3 | Cocoa cashew milk | 32 | 125 | 100 |

| 4 | Original peanut milk | 33 | 125 | 100 |

| 5 | Kale peanut milk | 32 | 125 | 100 |

| 6 | Cocoa peanut milk | 38 | 125 | 100 |

| 7 | Sugar-free macadamia milk | 25 | 125 | 100 |

| 8 | Sugar-free cashew milk | 25 | 125 | 100 |

| 9 | Sugar-free macadamia, cashew, peanut, black sesame milk | 24 | 125 | 100 |

| 10 | Macadamia, cashew, peanut, black sesame milk | 30 | 125 | 100 |

30. How to store Ready2Blend nut milk?

31. The nutritional content in Ready2Blend nut milk?

100g of Ready2Blend nut milk contains the following nutrient ratios:

| The nutritional content in 100g of nut milk butter | Energy | Protein | Starch | Fat | Carb | Sodium | Fiber |

| Cashew milk | 95,4 | 2,8 | 7,3 | 6,2 | 4,7 | 0,0 | 0,8 |

| Beet cashew milk | 80,4 | 2,3 | 7,3 | 4,8 | 4,8 | 0,0 | 0,6 |

| Cocoa cashew milk | 100,6 | 3,0 | 8,6 | 6,2 | 5,9 | 0,0 | 0,8 |

| Peanut milk | 105,5 | 4,0 | 7,2 | 7,6 | 5,5 | 0,0 | 0,9 |

| Kale peanut milk | 105,1 | 4,2 | 6,8 | 7,7 | 4,7 | 0,0 | 1,2 |

| Cocoa peanut milk | 112,8 | 4,3 | 8,9 | 7,6 | 6,8 | 0,0 | 0,9 |

| Sugar-free macadamia milk | 730 | 7,8 | 14 | 75 | 0,0 | 0,0 | 0,0 |

| Sugar-free cashew milk | 554 | 21 | 30,2 | 47 | 5,9 | 0,0 | 3,2 |

| Sugar-free macadamia, cashew, peanut, black sesame milk | 605,4 | 16,4 | 17,2 | 55,5 | 3,3 | 0,2 | 6,2 |

| Macadamia, cashew, peanut, black sesame milk | 509,5 | 14 | 368,3 | 275,2 | 411 | 0,0 | 33,6 |

32. How should Ready2Blend nut milk be stored? What are the signs of spoiling Ready2Blend nut milk?

Đạt butter

1. Why is your brand called ĐẠT BUTTER?

2. How many types of peanut butter and cashew butter are there, in ĐẠT FOODS?

Peanut Butter Including: Smooth and Crunchy 3 size: 210g, 570g, 1kg

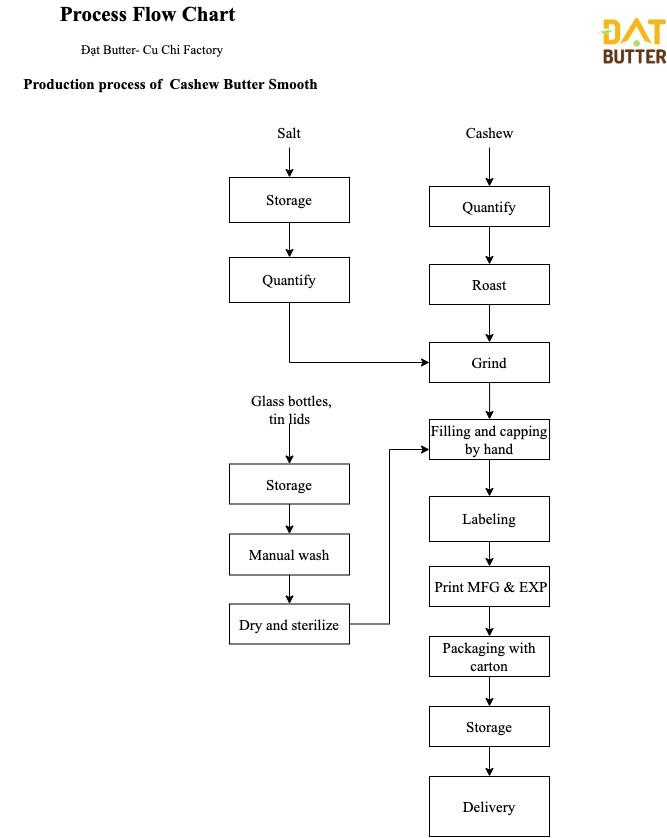

Cashew Butter Including: Smooth and Crunchy 4 size: 210g, 570g. 5kg, 15kg

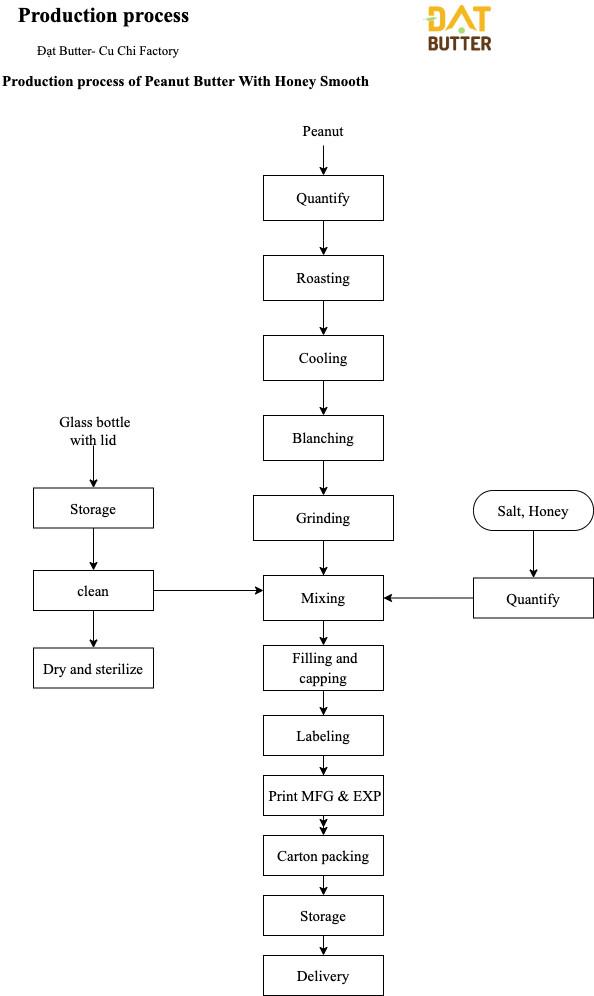

100% natural peanut butter: 100% peanut. Honey peanut butter: Peanut (96%), honey (3%), salt.

Natural cashew butter: cashew (99%), salt Cashew butter with cacao: Cashew (90%), cacao (6%), honey, salt

3. Nutrition Facts of peanut butter and cashew butter?

| Nutrition Facts | ||||

| Amount Per 100 grams | ||||

| % Daily Value* | Peanut Butter | Cashew Butter | ||

| Energy | 2,462 kJ (588 kcal) | 2,456 kJ (587 kcal) | ||

| Total Fat | 50 g | 76% | 49 g | 75% |

| Saturated fat | 10 g | 50% | 10 g | 50% |

| Polyunsaturated fat | 14 g | 8 g | ||

| Monounsaturated fat | 24 g | 29 g | ||

| Cholesterol | 0 mg | 0% | 0 mg | 0% |

| Sodium | 17 mg | 0% | 406 mg | 16% |

| Potassium | 649 mg | 18% | 546 mg | 15% |

| Total Carbohydrate | 20 g | 6% | 28 g | 9% |

| Dietary fiber | 6 g | 24% | 2 g | 8% |

| Sugar | 9 g | 5 g | ||

| Protein | 25 g | 50% | 18 g | 36% |

| Minerals | ||||

| Vitamin A | 0.0 IU | 0% | 0.0 IU | 0% |

| Vitamin B-6 | 25% | 0.3 mg | 15% | |

| Vitamin B-12 | 0% | 0.0 mcg | 0% | |

| Vitamin C | 0 mg | 0% | 0.0 mcg | 0% |

| Vitamin D | 0 mg | 0% | 0.0 mcg | 0% |

| Minerals | ||||

| Calcium | 4% | 43.0 mg | 4% | |

| Iron | 10% | 5.0 mg | 27% | |

| Magnesium | 38% | 258 mg | 64% | |

| * Percent Daily Values are based on a 2,000-calorie diet. Your daily values may be higher or lower depending on your calorie needs | ||||

4. What are the benefits of Peanut Butter for health?

Vitamins and Minerals: Another reason why peanut butter is a favorite is because it contains lots of vitamins and minerals, including vitamin E, B3, and B6. It also has folate, copper, manganese, magnesium, and iron.

Antioxidants: Because peanut butter comes from peanuts that have high amounts of antioxidants, peanut butter also has them, including p-coumaric acid. This antioxidant can decrease the risk of developing stomach cancer.

Resveratrol: Also found in red wine, peanut butter has resveratrol, which can help lower cardiovascular disease risk.

(Source: https://www.stethnews.com/0255/health-advantages-and-disadvantages-of-eating-peanut-butter/)

5. What are benefits of Cashew Butter for health?

– Less Fat Laden Than Other Butter Types: Like most of you already know, no nut butter is devoid of fat.The same is true for cashew butter. However, you intake far less amount of fat by eating cashew butter compared to peanut butter, and other types of nut derived butter. In a tablespoon of cashew butter, you get 94 calories, which is less than other variants. Cashew butter also contains less sugar than peanut butter.

– Source Of Protein: The protein quotient in cashew butter is lower than that of peanut butter. However, it can still serve as a good vegetable source of protein. If you eat less amount of animal meat (known to be a good protein source), make it up by taking cashew butter with the meals.

– Source Of Iron And Selenium: Cashew butter contains a fair amount of iron. Without iron, you may be subjected to anaemia and fatigue. Raw cashew butter should be eaten for optimum iron consumption. This butter also contains Selenium. This is vital for health as it fights free radicals and stops them from damaging the DNA membrane and cells.

– Important For Cardiac Health: Everyone wants to keep their heart healthy and properly functioning. For strong cardiac health, it is advisable that you include cashew butter in your diet. Its monounsaturated and polyunsaturated fats help fight the development of harmful cholesterol levels in the body. This in turn reduces the risk of various heart ailments.

– Helps Thwart Diabetes: There is no denying the epidemic nature diabetes has assumed all over the world. Diabetics are forced to live life with several restrictions, and it is better to prevent the disease from happening rather than fighting it after discovering! To keep diabetes at bay, you should include cashew butter in your meals. It helps regulate blood sugar levels, and thus thwart diabetes.

– Risk Of Gallbladder Stones: Gallbladder stones can be quite painful and annoying. Studies have shown women can bring down the risk of developing gallbladder stones by eating cashew butter.

(Source: http://www.stylecraze.com/articles/health-benefits-of-cashew-butter/#gref)

6. What are the dishes made from peanut butter?

– Processing smoothies: peanut milk; banana, apples smoothies,…

– Making cake, pizza, sauce, making peanut chocolate candy …

– Spice up the sauce, the salad …

– For further information https://staging.datfoods.vn/recipes/

7. What are the differences of Đạt Butter’s Peanut Butter?

– No chemicals, pesticides, preservatives.

– Peanut butter processing does not reduce the natural nutrient in peanuts, typically monounsaturated fats quotient reducing cholesterol in the blood.

8. Where is the peanut butter produced?

agricultural products in all parts of the country, ĐAT BUTTER have already transferred its

planting process into Hòa Bình (4 households), Hà Tĩnh (12 households), HCM (1 household).

At now, ĐẠT BUTTER factory is located Hoa Phu Commune, Cu Chi District, Ho Chi Minh

City.

In the future, its processing workshops are aimed to be positioned at all cultivation areas in

order to create specific regional flavour for each product

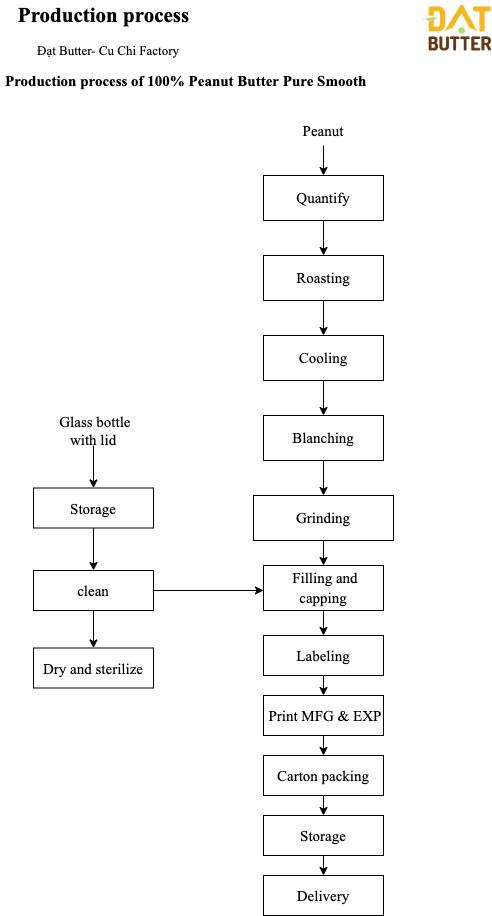

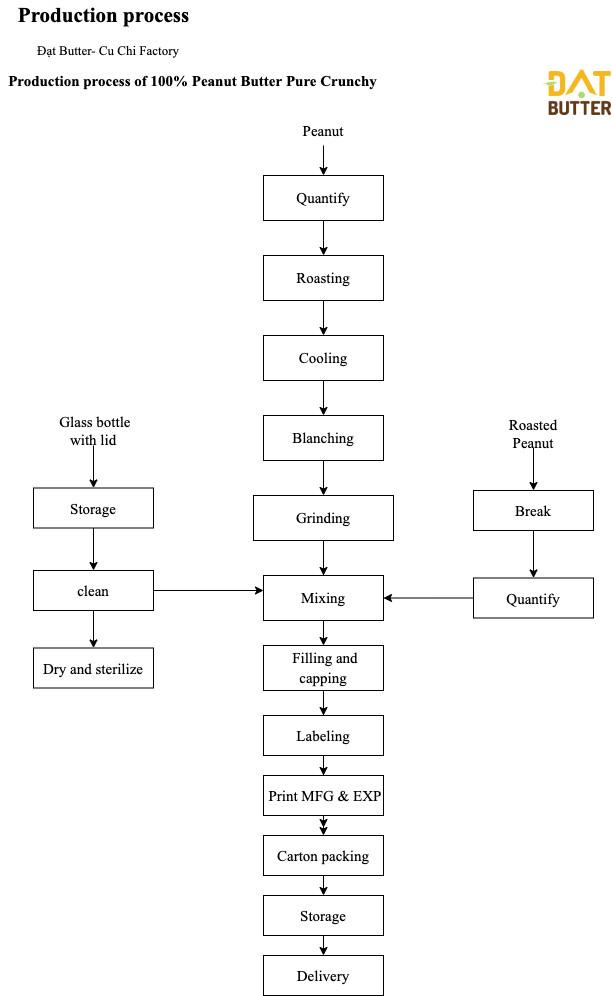

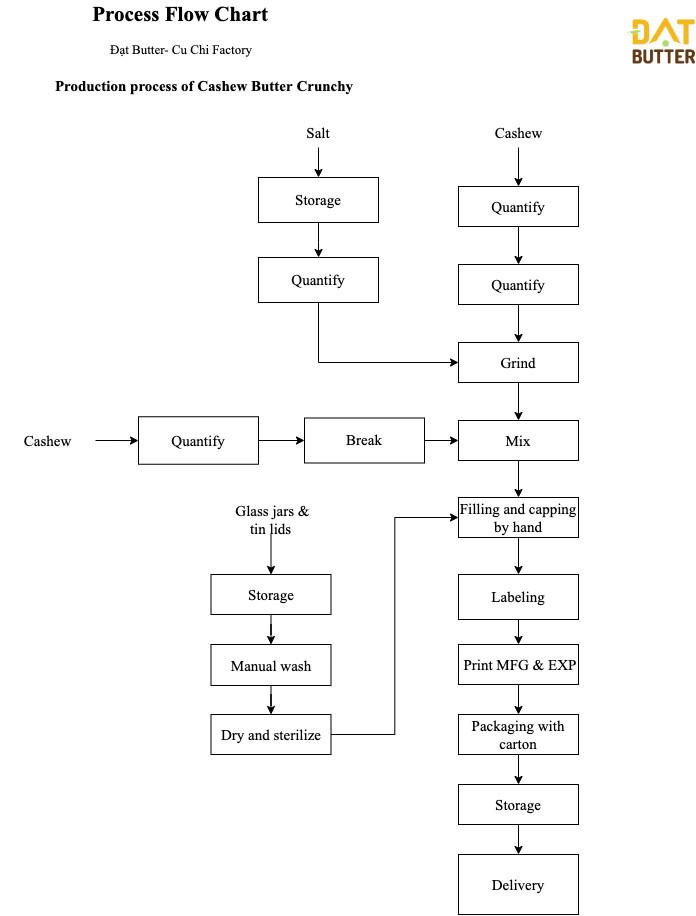

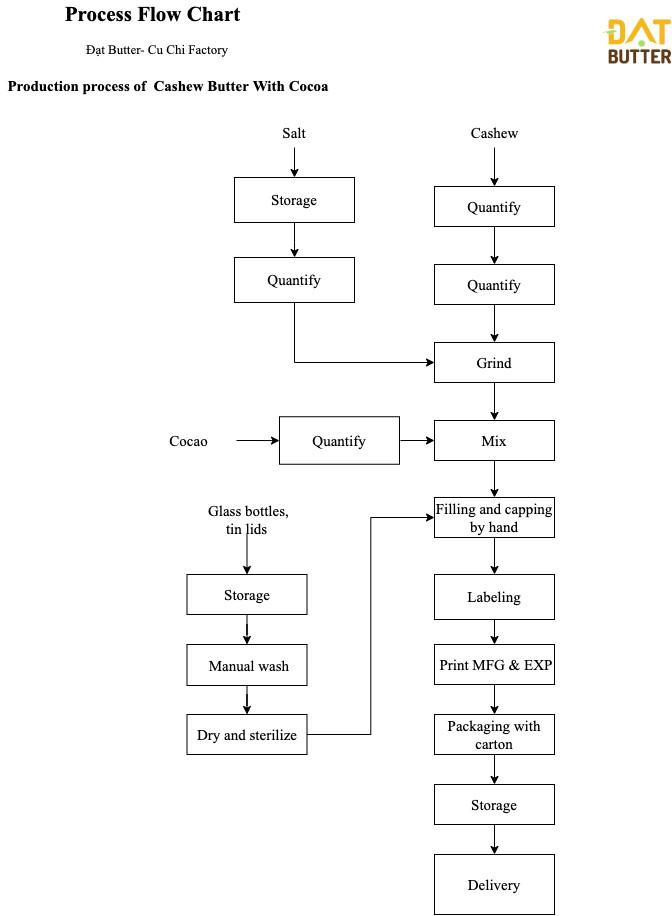

9. What is the process ĐẠT BUTTER use to produce nut butter?

10. Why do nut butter products have oil splitting?

using additives, emulsifiers (bonds between oil, water and other substances), nut oil can be

separated with the creamy part after opening.

11. Why are ĐẠT FOODS’s peanut butter products more expensive than others?

during the peanut cultivation.

Neither use additives, preservatives, nor sugar in processing process.

12. How long does the expiry date of butter products last?

life of 7 months. Once opened, use within 3 months.

Butter can expire before the time stated on the package when the butter is “contaminated”,

contaminated with bacteria from the external environment, or improperly stored.

After a period of use, the butter has the phenomenon of separating oil, a layer of oil will float

to the surface of the butter jar. This is normal, not a sign of spoiled butter. To continue using the

butter, simply mix it with a clean spoon.

13. How to grow peanuts? How to make sure they are spontaneous?

● No chemical fertiliser

● No pesticides

● No herbicide

Households or individuals involved in the peanut supply chain for Đạt Foods only use some

of the natural insecticide to provide adequate nutrition for peanut plants and prevent them from

pests and diseases.

A detailed procedure that has been developed by Đạt Foods and experimented at a garden in

Cu Chi is below:

Soil preparation ???? Fertilizing ???? Seeding ???? Weeding ???? 1st added fertilize ???? Root cultivation ????

2nd added fertilize ???? Harvest.

Following are the recommended facilities for the procedure by Đạt Foods:

● Lime Powder

● Phosphate Van Dien

● Trichoderma

● molasses

● Kitchen ashes

● Chicken egg shell

● Humid Acid Fertiliser

● Composted chicken manure with EM preparations and green and brown materials.

To answer the question how to ensure that peanuts are planted completely naturally, Đạt

Foods will share Đạt Foods’s participating and supervising process in order to support farmers

and individuals before sowing seeds, during cropping, caring and post harvesting as follows:

13

Stage 1: Pre-breeding: Find out the experiences and knowledge of the households involved

in production (Households will register in the registration form and be interviewed about

participating motivation and capacity), share materials to support more knowledge about

alternative plant-based insecticides in place of herbicides, chemical fertilizers, and pesticides. For

instance, instead of the usage of chemical fertilizers, farmers can use apatite, bone flour, bile

excrement …

Stage 2: Sign the agreement: plan for budget and production plan with the support of

technical collaborators of Dat Butter in each region.

Stage 3: During the process of cropping and tending: technical collaborators will visit the

garden regularly to monitor and solve arising problems involved in natural cultivation.

Stage 4: Post harvest: Collaborators will participate in the household harvesting process.

After drying, peeling and classifying beans, Đạt Butter will check periodically by sampling

produce for experiment.

Thus, to ensure a completely natural produce, Dat Butter is not only based on the motivation

and capacity of participating households, but also has a system of technical collaborators and pre,

during and post harvesting finished product monitoring mechanisms.

14. How do you reuse jars due to using glass jars to store your products?

jars. The process of returning the jar is as follows:

Step 1: Customers bring used glass jars of Dat Butter to stores that are selling Dat Butter’s

products.

Step 2: Each used glass jar of Dat Butter will receive a discount of 3,000 VND/jar for

purchases with Dat Butter products.

Step 3: At the end of each month, Dat Butter’s staff will collect jars at your store and pay

cash for the corresponding number of jars.

The reused program applies with 30g, 150g, 240g, 500g, 210g, 570g Đạt Butter’s products.

15. Can you tell more about honey, salt used in your products?

lak forest.

Salt is supplied by marine salt source of HomeFood or natural salt by Visaco.

In particular, in all products of Đạt Foods, there is absolutely no SUGAR.

16. How long does the butter last after opening without using refrigerators? What difference

is it if butter jars are preserved in refrigerators?

● Ensure peanuts are scooped, stirred with clean tools

● After using, customers should close the lid tightly and store the product in a dry, cool

place, avoid the sun. (Without refrigerator)

● The quality of peanut butter preserved in the refrigerator and the room temperature (28°C)

is usually the same.

● If you keep it in the refrigerator, after taking it out to easily scoop out the butter, you can

leave it out at room temperature for 5-10 minutes, the butter will be soft and very easy to

use. The butter in the refrigerator just taken out is still good to use, but it will be a little

tough.

17. If you have any questions about the product, how will I contact you?

Hotline: +84 9377 60624 or

Email: Hello@DatFoods.vn or

Website: www.datfoods.vn or

Fanfage: https://www.facebook.com/datfoodsvn

Đạt Oil

1. What is the household’s cultivation of peanuts and sesame? Where is the planting area?

– Households or individuals involved in the peanut supply chain for Đạt Oil only use some of the natural insecticide to provide adequate nutrition for peanut plants and prevent them from pests and diseases.

– A detailed procedure that has been developed by Đạt Oil and experimented at a garden in Cu Chi is below:

– Following is the recommended facilities for the procedure by Đạt Butter:

Lime Powder

Phosphate Van Dien

Trichoderma

Molasses

Kitchen ashes

Chicken egg shell

Humic Acid Fertiliser

Composted chicken manure with EM preparations and green and brown materials

– Raw materials are grown in many regions of Vietnam: To spread the spirit of “Natural” in the agricultural products in all parts of the country, ĐAT BUTTER has already transferred its planting process into Hòa Bình (4 households), Hà Tĩnh (12 households), HCM (1 household). The total area is 80,000 m2

2. How many types of peanut oil and sesame oil?

Peanut oil

Size: 250ml, 500ml, 2 litre

Sesame oil: Golden and Black sesame oil

Size: 250ml, 500ml, 2 litre

3. What is the production process for sesame oil?

4. What is the production process for peanut oil?

5. Compare the advantages and disadvantages of cold pressed and hot-pressed peanut oil/

sesame oil?

6. The benefits of peanut oil?

reduce bad cholesterol. From there, helps prevent cardiovascular diseases and increase

cardiovascular health

Helps fight cancer: The polyphenol antioxidants in peanut oil fight free radicals, contributing

to cancer prevention.

Regulating blood sugar: Studies show that a combination of monounsaturated and

polyunsaturated fats (found in peanut oil) can enhance insulin sensitivity in diabetics and help

with diabetes. The body feels less hungry. Replacing saturated fat with polyunsaturated fats helps

improve insulin secretion in diabetics.

Reducing the speed of aging: The vitamin E in peanut oil is important for the immune system

to function, is a powerful antioxidant, helps prevent early signs of aging.

Peanut oil is high in calories, but high in unsaturated fat and it feels full. If used in moderate

doses, it will help with weight loss.

7. The benefits of sesame oil?

reduce bad cholesterol. From there, helps prevent cardiovascular diseases and increase

cardiovascular health

Helps fight cancer: The polyphenol antioxidants in peanut oil fight free radicals, contributing

to cancer prevention.

Regulating blood sugar: Studies show that a combination of monounsaturated and

polyunsaturated fats (found in peanut oil) can enhance insulin sensitivity in diabetics and help

with diabetes. The body feels less hungry. Replacing saturated fat with polyunsaturated fats helps

improve insulin secretion in diabetics.

Reducing the speed of aging: The vitamin E in peanut oil is important for the immune system

to function, is a powerful antioxidant, helps prevent early signs of aging.

Peanut oil is high in calories, but high in unsaturated fat and it feels full. If used in moderate

doses, it will help with weight loss.

8. Advantages of the production process of Dat Foods compared to conventional nut oils?

Đạt Foods do not use Hydrogenation technology in any stage of products.

The oil pressing process always ensures a temperature of 160-180 degrees Celsius in 3-5

seconds, preventing the oil from chemical and physical changes, keeping the maximum

nutritional content and ensuring microbiological safety.

Peanuts are peeled and no residue is added to maximize the amount of oil to ensure that the

oil does not get malnourished.

9. Why are peanut oil bottles dark?

oil oxidation to occur quickly and produce substances that are not beneficial for the body. So the

bottle of the product is dark. When storing, you should also pay attention to shady places, avoid

hot places or direct sunlight.

10. Why does this product have a strong peanuts/sesame smell?

3-5 seconds with a temperature of 160-180 degrees Celsius so there is still the natural taste of

pure peanuts, namely the smell of peanuts/sesame.

To limit the smell of peanuts/sesame when cooking, you should note a few things:

Let pan dry completely before cooking.

Put the oil in a pan so that the oil starts to cook, you can add the garlic onions to deodorize

the smell. If you see smoke rising, you should lower the fire and then add the garlic onions

because peanut oil has a high smoke point, which burns the onions easily.

For sesame oil is often used to eat directly such as salad, soup, porridge….

11. How long is the shelf-life?

Depending on storage conditions, the shelf life after opening of oil varies.

21 – 30 degree celsius: 3 months

11 – 20 degree celsius: 6 months

01 – 10 degree celsius: 9 months

Therefore, to use for a long time, Đạt Foods’ oils after opening should keep in a cool, shady

place or cool refrigerator.

12. How to use peanut oil?

This oil is suitable for processing many dishes, especially vegetarian dishes. Peanut oil is also

suitable for savory dishes and especially suitable for stir-frying, mixing … making the dish more

delicious and attractive.

Fry: Low-fat peanut oil and light fragrance should be suitable for frying, especially fried

fish

Stir-fry vegetables: When using peanut oil to stir-fry vegetables, the vegetables will be

green, crunchy and very delicious.

Cook meats, fish: When steaming or cooking fish, you can use peanut oil when cooking

to reduce the fishy smell of meat and fish

When porridge or stirring flour for children can give a small amount of peanut oil into it.

Seasoning: add a little oil after mixing and marinating. If you put the oil in first, the

seasoning won’t get in well.

Baking: When baking food, put some oil on the surface to make the dish not dry and have

a nice yellow color that will be more attractive.

Making salad: peanut oil can be used as a sauce for salads (with vinegar, pepper, salt)

Beauty: Vitamin E in peanut oil is a powerful antioxidant, suitable for making moisturizers

and moisturizers for skin, lips, and hair. Peanut oil can also be used to massage the body.

Skin Beauty: Peanut oil can be a moisturizer that moisturizes the skin and contains lots of

vitamin E so it helps prevent premature aging.

Hair care: Peanut oil enhances moisture for the hair, regenerates damaged hair, thickens

hair. Moreover, because of its anti-inflammatory properties, it will help reduce flaking

and peeling of the scalp, reducing dandruff effectively.

Using therapy, body massage: Using peanut oil to massage will help the body relax and

ease body aches.

Lip balm: Peanut oil can be used as lip balm to soften lips especially in the dry season.

13. How to use sesame oil?

14. Is peanut oil when cooking in very high temperatures affected?

evaporate compounds such as water, free fatty acids, and short-chain decomposition products of

the oxidation that rise from oil in the form of Pale green smoke could be clearly seen.

At the smoke point temperature, the oil decomposes, oxidizes and forms related toxic

compounds such as aldehyde and lipid-peroxide (lipid oxidation products).

Use peanut oil when cooking at a temperature lower than or equal to 160 degrees Celsius to

retain the maximum nutritional content of peanut oil. The smoke point of natural sesame oil is

176 degrees Celsius, so it is recommended to use it directly without cooking to ensure nutrition.

Đạt Foods’ peanut oil and sesame oil are recommended to be used directly without frying

because Đạt Foods’ oil has a natural smell and the most complete nutrition.

15. For dieters, afraid of being fat, is using this product any effect?

weight loss.

Saturated fat (trans fat) is a type of fat formed by hydrogenation of cooking oil, to help foods

be preserved longer, eye-catching and more attractive to consumers. Saturated fat raises the level

of lipoproteins and triglycerides, increases the level of bad cholesterol (LDL-C) and lowers the

amount of good cholesterol (HLD) in the blood, which increases the risk of cardiovascular

disease, stroke and diabetes.

In contrast, unsaturated fat lowers bad cholesterol (LDL-C), but can raise good cholesterol

(HLD). Large-scale research suggests that increasing monounsaturated fat and reducing saturated

fat intake may improve insulin sensitivity when the overall fat content of the diet is low. Regular

use helps reduce the risk of cardiovascular disease, overall cancer, neurodegenerative disease,

diabetes

16. Does your product use partially hydrogenated technology?

hydrogenation technology is the process of changing the chemical formula of vegetable oils from

saturated fatty acids to unsaturated fatty acids. Liquid oil after hydrogenation will reduce the rate

of unsaturated fatty acids, reducing the ability of oil oxidation.

The advantage of this method is that it makes the oil easier to store and facilitates the

processing of other products.

The disadvantage of this process, however, is that it increases the amount of unsaturated fat

in the oil, raises bad cholesterol (LDL) while lowering good cholesterol (HDL), making it a major

cause of heart disease.

17. If you have any questions about the product, how will I contact you?

Hotline: +84 9377 60624 or

Email: Hello@DatFoods.vn or

Website: www.datfoods.vn or Fanfage: https://www.facebook.com/datfoodsvn

our membership

1 question 1

2 What is interlock fabric?

Easy to sew it holds its shape well, making it ideal for fitted garments.

3 What is circular knitting fabric?

As warp-knit and interlock, also circular knit fabric is two-way stretch, with application suitable for high-end and also form-fitting lingerie, according to its weight and surface.

4 Polyamide fabric, Polyester fabric, what is the difference?

Polyamide is a synthetic material derived from petroleum, which first became available around World War II and was used for military products and as a silk replacement for items like stockings. Now, we’re more likely to find it in activewear, swimwear and other technical performance garments because of its durability and useful stretch properties. Polyamide fabric is commonly known as Nylon and it is made by a compound of chemical components, resulting in a long-chain chemical structure which is then extruded, spun into filaments and warped onto beams, to be suitable for different knitting processes. Nylon fabric is lightweight, durable and abrasion-resistant, making it a popular choice for a variety of applications such as clothing, outdoor gear, luggage, and industrial materials. Polyamide yarn can be weaved and knitted into a variety of fabrics: from smooth, to textured and it is suitable to be dyed in a wide range of bright colors. The hand feeling of Polyamide fabric is overall comfortable and silky-smooth, depending on the fabric and application it is designed for.

Polyester fabric:

Polyester fabric also originated from a chemical reaction of elements of fossil origins – Petroleum to be specific – resulting in a long-chain chemical structured polymer, that is extruded into filaments and then spun onto coils to be applied to different knitting processes. Polyester fabric is known for its durability, resistance to high temperatures, wicking properties, wrinkle resistance, chlorine resistance performances and the ability to retain its shape, even after repeated washings. It is also quick-drying, making it ideal for outdoor and sportswear; it can also be used for performance swimwear. The hand feeling of Polyester fabric is overall comfortable, cotton-like and soft, according to the type of yarn and the applications it is designed for.

What is the difference between Polyamide and Polyester fabric?

- Chemical composition: Polyamide 6 is obtained by the polymerization of caprolactam. Polyester is originated from a chemical reaction in which ethylene is the original raw material;

- Melting point of Polyamide is around 220 ℃, while Polyester resists to higher temperature, till 260 ℃;

- Melting point of Polyamide is around 220 ℃, while Polyester resists to higher temperature, till 260 ℃;

- Polyamide preferred dyeing process implies the use of acid dyestuff, while for Polyester reactive dyestuff under pressure with high temperature;

- Applications: Polyester is used mostly for clothing, specifically t-shirts and sportswear. It is versatile and can be used to make both cold and warm weather clothing. Polyamide is used for sportswear and outerwear, such as jackets, but given its embedded elastic properties it is used to make legwear, swimwear, and underwear garments;

- Durability: Both fabrics are durable and resistant to abrasion, tearing, punctures, UV radiation and color fading.

- Comfort: Polyamide fabric tends to feel smoother and softer to the touch, while polyester fabric can feel slightly stiffer with good compressive power properties;

- Breathability and Wicking: Polyamide is generally considered to be more breathable than Polyester, and a more indicated choice for swimwear because it dries faster. Polyester is more likely used in sportswear, for its thermic-adaptive and compressive properties. It is important to note that the breathability as much as the wicking properties of both fabrics, can vary depending on a range of factors, such as fabric weight, knitting construction, and finishing treatments. For example, a lightweight Polyester fabric with a loose construction, may be more breathable than a heavyweight Polyamide fabric with a tight construction;

- Colorfastness: Polyamide is more sensitive to light, chlorine and perspiration fading, while Polyester to washing, temperature, crocking, water and seawater fading.

- Stretching properties: Polyester is overall considered more rigid than Polyamide with a lower capacity to absorb water. Its extension capacity is around +30% of its original length, while Polyamide 6.0 is around +30-45%.

5 Post-consumer and Post-industrial Recycled Polyamide,

what is the difference?

<meta itemprop="name" content="5 Post-consumer and Post-industrial Recycled Polyamide,Performance characteristics, and costs may vary depending on the specific factor, such as origin of the regenerated raw material and availability.

Post-consumer Recycled Polyamide, also known as post-consumer Nylon, is made from wastage regenerated materials, such as discarded fishing nets, carpets, and mono-components clothing. The waste material is collected, sorted, cleansed and processed chemically to become new fibers and yarns for new raw material porpoise.

Post-industrial Recycled Polyamide, also known as pre-consumer Nylon, is made from waste materials generated by the yarn and textile manufacturing process. These materials can include items like leftover textile Nylon scraps, trimmings, and offcuts. The waste is collected, sorted, and chemically processed to become new fiber and yarn.

Our Tour

1 What is warp-knit fabric?

Warp-knit fabrics can be made from a variety of fibers, including synthetic materials like polyester and nylon, as well as natural fibers like cotton and wool. They are used in a wide range of applications, especially sportswear, swimwear, outerwear, lingerie, upholstery, and industrial textiles. Warp-knit fabrics is ideal for garments that require high flexibility and movement.

2 What is interlock fabric?

Easy to sew it holds its shape well, making it ideal for fitted garments.